08045805199

Have any question?

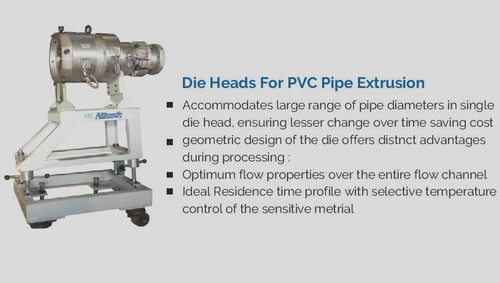

Pipe Extrusion Die Head

900000.00 - 3000000.00 INR/Piece

Product Details:

- Type PLASTIC MACHINERY

- Capacity KG Kg/hr

- Computerized Yes

- Automatic Grade Semi-Automatic

- Control System PLC Control

- Click to View more

X

Pipe Extrusion Die Head Price And Quantity

- 900000.00 - 3000000.00 INR/Piece

- 1 Piece

Pipe Extrusion Die Head Product Specifications

- PLASTIC MACHINERY

- Semi-Automatic

- PLC Control

- KG Kg/hr

- Yes

Pipe Extrusion Die Head Trade Information

- MUMBAI

- 1-2 Piece Per Month

- 1-2 Months

- Yes

- If order is confirmed we will reimburse the sample cost

- All India

- Complete die head u inner coating die head Without die & seizer. With inner outer coating.(3 Layer)

Product Description

This PLC controlled Pipe Extrusion Die Head has multi cavity design so that materials can be flown through each of its cavity smoothly. Its design has been created by keeping different properties of PVC and PE. Advanced design of this die head maintains smooth surface quality and extends service life of produced pipes. Offered Pipe Extrusion Die Head has temperature controlling and adjusting arrangement for sensitive raw materials. Provided Pipe Extrusion Die Head does not require replacement. Thus it saves production time, duration and effort. This die head can be computer controlled.

Product Details ofPipe Extrusion Die Head:

- Complete die head inner coating die head Without die & seizer.

- With inner outer coating (3 Layer).

Precision Engineering for Pipe Production

Our Pipe Extrusion Die Head is crafted to offer exceptional precision and uniformity in plastic pipe manufacturing. The semi-automatic system, guided by an advanced PLC control, brings stability to your line and minimizes operator intervention, making it suitable for large-scale or small batch production alike.

Versatile Applications Across Industries

This specialized extrusion die head can be adapted for multiple types of plastic materials, catering to various diameters and thickness specifications. Whether you require tailored solutions for plumbing, construction, or industrial piping, this equipment allows for reliable and customizable performance.

FAQs of Pipe Extrusion Die Head:

Q: How does the PLC control system enhance the operation of the Pipe Extrusion Die Head?

A: The PLC (Programmable Logic Controller) system streamlines the extrusion process by automating critical parameters like temperature, pressure, and speed, allowing for greater consistency, reduced error, and improved safety during semi-automatic operation.Q: What types of plastic pipes can be produced using this extrusion die head?

A: This die head is versatile and designed for various thermoplastic materials such as PVC, HDPE, and PP, accommodating a wide range of pipe diameters and thicknesses as per your production needs.Q: When should maintenance be performed on the extrusion die head?

A: Routine maintenance is recommended after each production cycle or as per your companys schedule. Regular cleaning of the die head ensures consistently high-quality output and extends equipment life, especially important in industrial environments.Q: Where can I procure this Pipe Extrusion Die Head in India?

A: We supply this product all over India through our extensive network of dealers, distributors, exporters, manufacturers, producers, service providers, suppliers, traders, and wholesalers. Contact us directly for the nearest authorized representative or distributor.Q: What is the process for installing and commissioning the die head?

A: Installation involves mounting the die head onto your extrusion line, connecting it to the PLC system, and calibrating it according to your chosen material and pipe specifications. We provide comprehensive support and user manuals to facilitate efficient setup.Q: How is the extrusion die head typically used in pipe production?

A: The die head shapes molten plastic material as it is pushed through the extrusion line, forming it into the desired pipe dimensions. Adjustments via the PLC system ensure accurate production tailored to various industry standards.Q: What are the primary benefits of using a semi-automatic, PLC-controlled die head?

A: Key advantages include increased production consistency, ease of operation, enhanced safety, and the ability to quickly switch between pipe sizes or materials, making your manufacturing process more adaptable and efficient.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese